How Electric Construction Machines Pave the Way to an Emission-Free Future

Across Switzerland, pilot construction sites are emerging that demonstrate how future building processes can be emission-free, quiet, and efficient. Cities, universities, authorities, and industry partners are working together to test electric construction machinery under real conditions and make its potential visible.

Zürich: Insights into Emission-Free Construction Operations

At various construction sites in Zürich, SUNCAR’s fully electric excavators were deployed. The machines are designed for high battery capacity, fast charging capability, and intelligent connectivity. Its use provided valuable hands-on experience in daily construction operations and contributed important insights to the discussion on emission-free construction - particularly in areas with strict noise and emissions regulations.

Basel: Electromobility as a Pilot Project in Civil Engineering

An especially ambitious project was taking place in Basel. A new underground recycling collection point was built on Hegenheimerstrasse - entirely using electric construction machinery. For the first time, the 15-ton electric wheeled excavator ZE150W was used, developed by SUNCAR in collaboration with KTEG and supported by the Swiss Federal Office of Energy (SFOE).

The project was part of the SFOE’s Pilot and Demonstration Programme and investigates the efficiency, economic viability, and practical suitability of large electric construction machines. This includes noise measurements, CO₂ analyses, and the optimisation of drivetrain systems. Basel’s goal is clear: by 2037, all construction sites should operate emission-free - a strong signal for climate-friendly infrastructure projects.

Lucerne: One of Switzerland’s Largest Electric Construction Sites

The city of Lucerne is also testing the construction site of the future. Several fully electric machines are in use on a major pilot site, including the 15-t ZE150W wheeled excavator and the 6-t TB260E crawler excavator. During a guided visit, more than 50 representatives from public authorities, the construction industry, dealers, manufacturers, and the Lucerne University of Applied Sciences and Arts exchanged insights and experiences.

On-site, various electric machines could be observed in real operation - from an electric road paver to a wheeled excavator. The insights into runtimes, charging processes, and operational challenges showed how initial skepticism toward electrification is steadily giving way to enthusiasm. The feedback from Lucerne makes it clear: the emission-free construction site is no longer a vision - it is a reality.

Digital Connectivity as a Success Factor

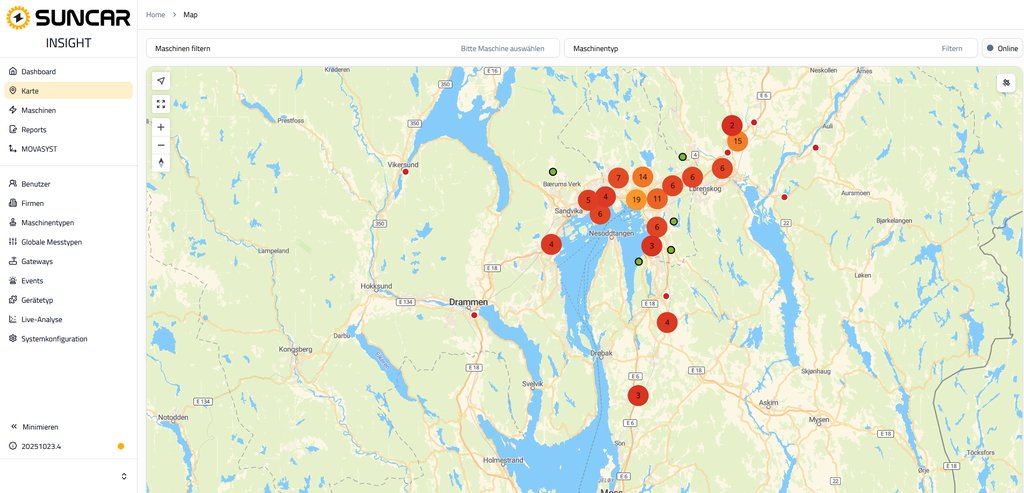

Another key element of this development is digital infrastructure. Through SUNCAR's telematics platform “INSIGHT,” machine data from many electric excavators is recorded and visualized online, making it easily accessible for service teams. Remote software updates are also possible - an important step that not only increases operational efficiency but also enables data-driven optimization.

International Outlook: Norway as a Pioneer

While Switzerland is beginning to scale up electric construction sites, Norway is already a step ahead. In Oslo alone, more than one hundred electric construction machines - many co-developed by SUNCAR -are in daily use. Clear regulations have played a major role in accelerating electrification there.

Conclusion: The Transformation Is in Full Motion

The pilot construction sites in Zürich, Basel, and Lucerne show how research institutions, the public sector, and industry are jointly shaping the next generation of sustainable construction machinery. Electric excavators, loaders, and road pavers are increasingly being tested in everyday operation - quiet, emission-free, and efficient.

The experience from these pilot projects demonstrates: the electrification of construction sites is no distant future. It is happening today - and its momentum is growing rapidly.